Z-Finder tool length sensor inductive PNP

NPN or PNP sensor:

How to choose the right one? |

The tool lenght sensor build with an inductive sensor are available with either NPN or PNP logic. They all need a power supply in order to work (usaully 24V), but the type of sensor depends of your wiring and controller board.

NPN : the sensor produces a negative signal during an "on" state

PNP : the sensor produces a positive signal during an "on" state |

The Z-Finder tool length sensor is designed for high measurement accuracy and repeatability.

In order to guarantee high repeatability, an inductive proximity switch

(opener) was used.

It has deliberately avoided the use of mechanical switches, because they have a poorer repeatability over a longer period.

The inductive sensor is working towards a mechanical button regardless of the state of contacts (oxidation), compressive force, ambient temperature and humidity. Even vibrations that occur when working with CNC machines and can cause contact bounce do not affect the switching point of the inductive sensor.

Advantages of Z-Finder

The use of non-contact sensor means for the user in any case, a plus in terms of accuracy, reliability and service life:

- very high repeatability

- no migration of the switching point position

- very reliably even with vibrations and shocks

- no limitation of life by the number of switching cycles

- no failure due to dirty or corroded contacts

- no contact bounce, because solid-state output

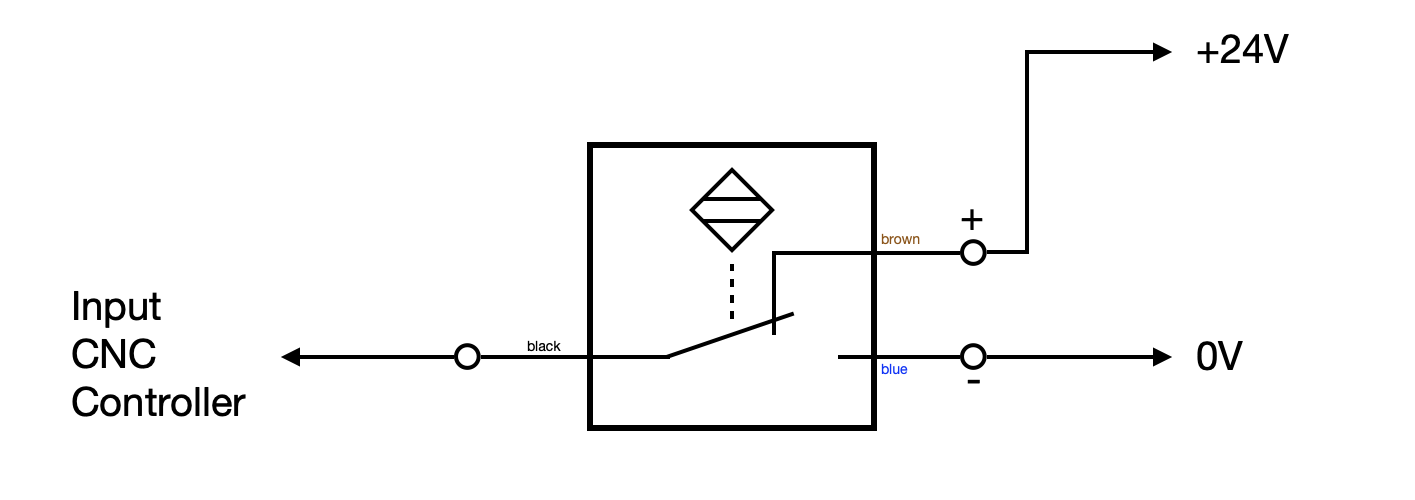

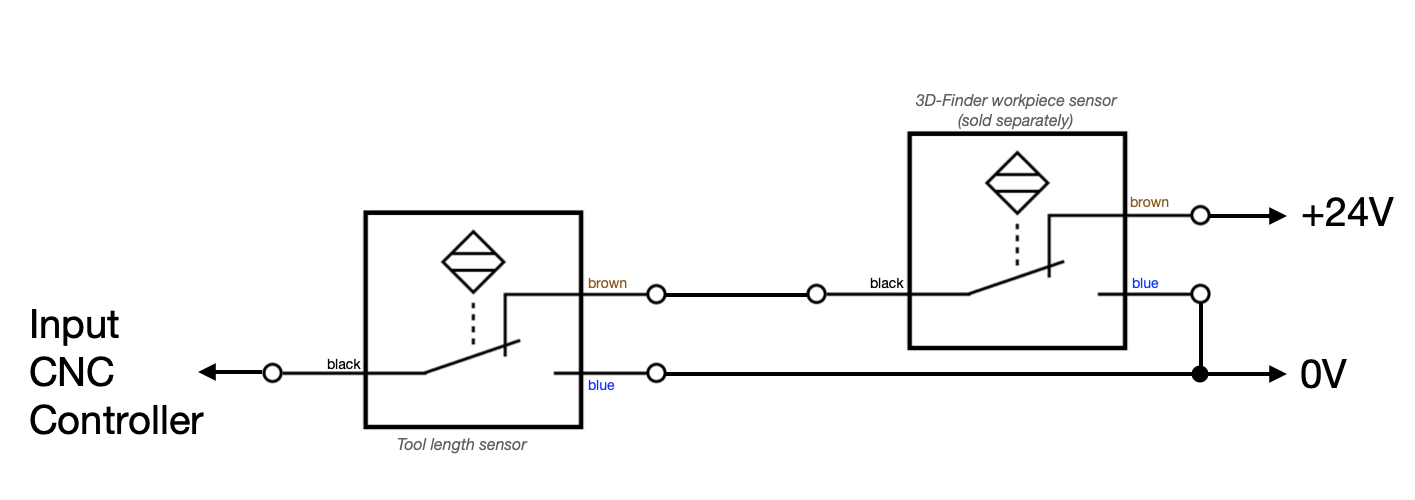

Wiring diagrams

Hotline: +49 (0)7227 994255-0

Hotline: +49 (0)7227 994255-0![]() E-Mail: web1@sorotec.de

E-Mail: web1@sorotec.de

Hotline: +49 (0)7227 994255-0

Hotline: +49 (0)7227 994255-0![]() E-Mail: web1@sorotec.de

E-Mail: web1@sorotec.de